- The Base Extension has been slightly redesigned to consume less material, increase the space for wires and decrease overall printing time

- The MK-X frame extension mount has also been slightly redesigned to follow the base extension as well

- The MK-X Top Frame Extension mount has also been updated

- A new material has been chosen for insulation

- The carriage mount is now at a 30 degree angle to allow for shorter arm lengths and increased height

- The neoprene GT2 belt has been replaced with Steel core GT2 belts

- A mounting plate is now in place over insulation over the Steel core belts to reduce thermal expansion in the chamber

- The NEMA17 motors have been replaced with updated ones

- 5mm Borosilicate glass has been replaced in lieu of 400mm diameter MIC-6 Aluminum

- The polyethermide aka Ultem build surface has been replaced by a FR-4 class composite material known as Printbite to serve as the new printing surface as it can adhere to nylon when heated.

- The silicon heater pad is now AC and 400 watts instead of 300 watts and 24V to decrease the danger of high currents

- The Smoothieboard controller has now been replaced by the Duet V.8.5. + Due X4 Expansion board

- The 600mm Hiwin MGN12-H linear rails have been replaced by V-slot wheel carriages

- The Misumi 2020 1m vertical extrusions have been replaced by 2020 1m V-slot extrusions

- The Misumi 2020 485mm horizontal extrusions have been replaced by 2060 V-slot extrusions

- The Kraken effector has been redesigned

- A dual IR sensor for 7-factor delta auto-calibration by DC42 has also been included

- A detachable blower fan/led ring/ and dual IR sensor design has been created

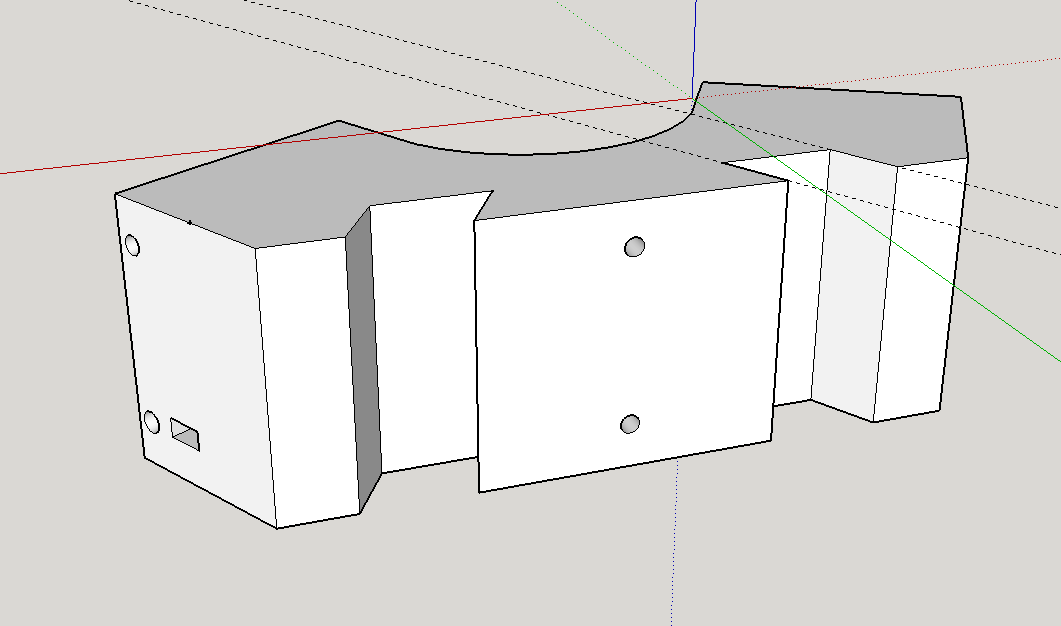

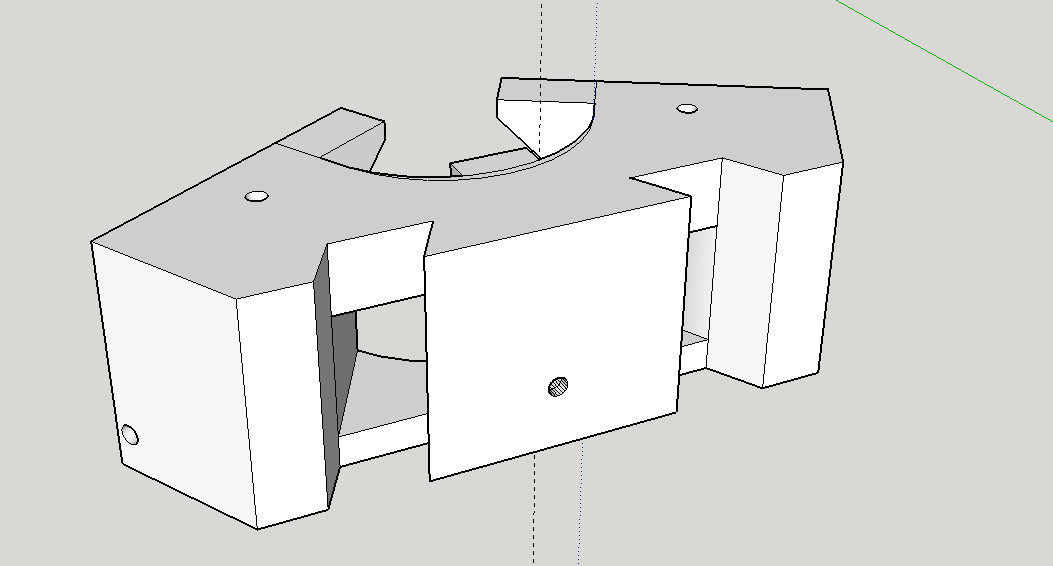

Base Extension:

This is the 3D model for the base extension and now has larger slots to feed larger gauge wire and sheathing comfortably without cable strain. It also contributes to lower print times and material costs. The base itself has been extended another 40mm to allow for allowance of the larger build plate.You can compare this to :

Frame Extension:

It can be seen that the design follows the Base Extension as it is placed directly on top of it. The top extension is only slightly modified from this design and will not be discussed.

Insulation material:

The insulation chosen now will be EPS - Expanded Polystyrene as it has decent flame retardation properties, coupled with aluminum plates as the exterior case, it will be able to insulate a majority of the heat.

Steel core GT2 Belts

Steel core GT2 belts were chosen to replace the standard neoprene GT2 belts as they have shown to have lower stretch at elevated heated chamber temperatures. The extra stiffness of the belts will help as each tower requires at least 2.1m of belt. A mounting plate will cover the belts over the vertical carriages for both aesthetics and insulation.

NEMA17 Replaced

The most common NEMA17 motors are 1.8 deg/step or 200 steps per rotation. To increase the resolution at lower layer heights and decrease visual artifacts and use .9 deg/step or 400 steps per rotation NEMA17 stepper motors.

400mm Alu Build Plate - Printbite

To adjust for a much larger plate, the glass plate has been dropped for MIC-6 grade aluminum plates to be very flat. The PEI was difficult to source at that size so Printbite is going to be used instead. Printbite has shown to be able to adhere to more materials than PEI itself and thus makes it very attractive.

NEMA17 Replaced

The most common NEMA17 motors are 1.8 deg/step or 200 steps per rotation. To increase the resolution at lower layer heights and decrease visual artifacts and use .9 deg/step or 400 steps per rotation NEMA17 stepper motors.

400mm Alu Build Plate - Printbite

To adjust for a much larger plate, the glass plate has been dropped for MIC-6 grade aluminum plates to be very flat. The PEI was difficult to source at that size so Printbite is going to be used instead. Printbite has shown to be able to adhere to more materials than PEI itself and thus makes it very attractive.

Duet V.8.5 + DueX4

The Smoothieboard controller was replaced in favor of the Duet board and its extension due to its ease of setup for 9-stepper motor control. 3 movement axis and 6 extruder channels. It also allows for quick hookup of the Dual IR sensor.

V-Slot Extrusions

The extrusions were replaced as part of using the V-slot linear motion components. The Linear rail originally purchased at 600mm was too short for full length of travel.

DC42 Dual IR Autocalibration Sensor

The IR sensor that DC42 allows for quick (~30sec) autocalibration before each print allowing for complete automation.

·